the pulley system of a mine shaft

11.2: Belt- and Gear-Driven Systems - Engineering

2021年7月28日 Belt-and-pulley systems, along with gear-driven systems, represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. Belts offer flexibility in that the shafts do not need to be right next to one

اObtener precio

Pulley - Wikipedia

A rope and pulley system—that is, a block and tackle—is characterised by the use of a single continuous rope to transmit a tension force around one or more pulleys to lift or move a load—the rope may be a light line or a strong cable. This system is included in the list of simple machines identified by Renaissance scientists.

اObtener precio

Mining – Conveyor Pulley Bearing Sealing - MRO Magazine

2018年12月3日 One of the most common pieces of equipment on a mine site is a belt conveyor. No matter what mineral is being extracted, this

اObtener precio

Hoist (mining) - Wikipedia

Friction (or Koepe) hoists are the most common type of hoist used in Europe, Asia and Australia. The friction hoist was invented in 1877 by Frederick Koepe. Friction hoists are mounted on the ground above the mine shaft, or at the top of the headframe. Friction hoists utilize tail ropes and counterweights and do not have the haulage rope fixed to the wheel, but instead passed around it. The ta

اObtener precio

The Pulley System It’s 4 Types, Applications, Working

2023年3月11日 The pulley system consists of the pulley and a rope, cable, or chain to drive it. In everyday life, we find many applications of pulley systems in gyms,

اObtener precio

Shafts Hoisting Systems - Stantec

Whether you’re designing a new mine, looking to examine existing infrastructure, or expanding capacity, we have skilled shaft and hoisting experts who work with you to

اObtener precio

Pulley System - Definition and Mechanism - VEDANTU

2023年3月21日 A pulley system that has a support frame or shell doesn't transfer power to the shaft. It is used to exert force and guide the cable in a specific direction. The shell,

اObtener precio

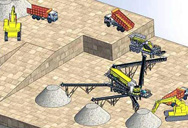

Common types of pulleys found in a conveyor belt

2022年6月28日 A conveyor system will always consist of a head pulley and a tail pulley. All pulleys are comprised of these components which include: End discs Locking element Bearing assembly Shell Shaft See

اObtener precio

Mine Shaft Head Gear - St Matthews High School

2016年3月13日 Members of the mine shaft have different characteristics. The members are as follows: Pulley-is used to pull the elevators that carry miners and minerals to/from

اObtener precio

Basic Pulley Mechanisms : 17 Steps (with Pictures)

The pulley is one of the six simple machines. Basically, all that a pulley is is a wheel spinning around an axle to aid the motion of a belt. The sprockets on a bike, for example,

اObtener precio

11.2: Belt- and Gear-Driven Systems - Engineering LibreTexts

2021年7月28日 Figure 11.2.4: The diagram above shows a multi-stage belt driven system connecting pulley A and pulley D. Pulleys A and B are connected via a belt, then B and C are on the same shaft, then C and D are connected via a belt. With pulleys on the same shaft, the angular displacements, the angular velocities, and the angular accelerations

اObtener precio

Shafts Hoisting Systems - Stantec

Whether you’re designing a new mine, looking to examine existing infrastructure, or expanding capacity, we have skilled shaft and hoisting experts who work with you to tailor designs to your needs. We have experience in shaft configuration, ground consolidation method, sinking method, and collar excavation. We also offer shaft collar and vent ...

اObtener precio

Mining – Conveyor Pulley Bearing Sealing - MRO

2018年12月3日 One of the most common pieces of equipment on a mine site is a belt conveyor. No matter what mineral is being extracted, this piece of equipment generally ... depending on the mechanism and design of

اObtener precio

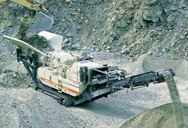

Stress–Strain Analysis of Conveyor Drive Pulley

2019年12月5日 The paper presents an analysis of the stress deformation state of shafts of characteristic drive pulleys on belt conveyors in Drmno open pit mine. The shape and dimensions of the shafts were ...

اObtener precio

The Pulley System It’s 4 Types, Applications, Working

2023年3月11日 The pulley system consists of the pulley and a rope, cable, or chain to drive it. In everyday life, we find many applications of pulley systems in gyms, construction sites, elevators, etc. The main function of the pulley system is to lift heavy weights with very little force input. The term “Pulley” is most probably derived from the word “pull”.

اObtener precio

Common types of pulleys found in a conveyor belt

2022年6月28日 A conveyor system will always consist of a head pulley and a tail pulley. All pulleys are comprised of these components which include: End discs. Locking element. Bearing assembly. Shell. Shaft.

اObtener precio

Pulley System: Mechanism, Types and Applications

2022年10月11日 The pulley system is employed on a shaft or wheel which uses the change in direction of the cable or a taute belt. The components of a pulley sysytem are: Wheel Hook Flexible Belt Axle

اObtener precio

Gr8 Technology - mstworkbooks.co

The hoist is attached to a motor and a control system. The mine cage and the skips are lowered into the mine when a steel cable unwinds from the winch. The mine cage and skips are raised when the steel cable winds

اObtener precio

Fact Sheet - South32

This shaft will draw air into the mine and will double as mine access. Proposed Ventilation Shaft No. 8 will be approximately 560 metres deep and 5.5 metres wide. This shaft will draw air out the mine. A ‘kibble’ is the bucket used to remove the broken-up pieces of rock during the ventilation shaft sink. It operates on a pulley system

اObtener precio

Mine Shaft Head Gear - St Matthews High School

2016年3月13日 Members of the mine shaft have different characteristics. The members are as follows: Pulley-is used to pull the elevators that carry miners and minerals to/from the work level. In a mine shaft, two pulleys are required. Crank-it’s a pole used to keep a pulley in place whilst the pulley rotates.

اObtener precio

Specification and Design of Shafts SpringerLink

2010年1月1日 Abstract. The specification and design of transmission shafts is of special significance in the layout of vehicle transmissions. Shaft diameters are a key factor in determining the centre distance of a gearbox, and thus its size. Strength and resistance to deformation must therefore be carefully considered during the design process.

اObtener precio

DESIGN OF MINE SHAFT ELEVATOR - mech-ing

When it comes to design of a mine shaft, there are two options: circular shafts and horizontal shafts (Figure 1, Figure 2). Circular shaft is the most commonly used one. If the shaft should be deep and shaft diameter is supposed to be more than 4.5 meters, circular shafts are the best choice. Because of their circular shape,

اObtener precio

How to Calculate the Size of a Mine Hoisting System

2017年2月4日 A = area of cylinder in sq. inches. L = length of stroke in feet. S = speed of hoisting in ft. per min. R = number of revolutions of engine per min. F = friction in pounds, f = coefficient of friction. r = ratio of diameter of piston to length of stroke, both being in feet or both in inches, = stroke/diameter d = diameter of piston in inches,

اObtener precio

Answered: A man uses a rope and a system of bartleby

A man uses a rope and a system of pulleys to raise a 200-lb box to a height of 10 ft. He exerts a force of 60 lb on the rope and pulls a total of 40 ft of rope through the pulleys. ... A mouse of mass 200 g falls 100 m down a vertical mine shaft and lands at the bottom with a speed of 8.0 m/s. During its fall, how much work is done on the mouse ...

اObtener precio

11.2: Belt- and Gear-Driven Systems - Engineering LibreTexts

2021年7月28日 Belt-and-pulley systems, along with gear-driven systems, represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. Belts offer flexibility in that the shafts do not need to be right next to one another, and gears are more commonly used in high-load applications.

اObtener precio

Shafts Hoisting Systems - Stantec

Whether you’re designing a new mine, looking to examine existing infrastructure, or expanding capacity, we have skilled shaft and hoisting experts who work with you to tailor designs to your needs. We have experience in shaft configuration, ground consolidation method, sinking method, and collar excavation. We also offer shaft collar and vent ...

اObtener precio

Mining – Conveyor Pulley Bearing Sealing - MRO

2018年12月3日 Most belt conveyors will have additional pulleys for tensioning the belt in some form, and, depending on the mechanism and design of the tensioning system, there could be multiple pulleys. A

اObtener precio

Stress–Strain Analysis of Conveyor Drive Pulley

2019年12月5日 The paper presents an analysis of the stress deformation state of shafts of characteristic drive pulleys on belt conveyors in Drmno open pit mine. The shape and dimensions of the shafts were ...

اObtener precio

How to Use a Single and Double Pulley System

2018年1月3日 Pulleys work by means of a grooved wheel that pivots around an axle. When the pulley is fixed to a solid anchor and a rope is threaded through the grooves on the pulley's wheel, it can be used to lift

اObtener precio

Pulley System: Mechanism, Types and Applications

2022年10月11日 The pulley system is employed on a shaft or wheel which uses the change in direction of the cable or a taute belt. The components of a pulley sysytem are: Wheel Hook Flexible Belt Axle

اObtener precio

Common types of pulleys found in a conveyor belt

2022年6月28日 A conveyor system will always consist of a head pulley and a tail pulley. All pulleys are comprised of these components which include: End discs. Locking element. Bearing assembly. Shell. Shaft.

اObtener precio

Gr8 Technology - mstworkbooks.co

The hoist is attached to a motor and a control system. The mine cage and the skips are lowered into the mine when a steel cable unwinds from the winch. The mine cage and skips are raised when the steel cable winds

اObtener precio

Line shaft - Wikipedia

The loose pulley ('idler') allows the machine to be stopped in isolation – necessary for changing speed. The stepped pulleys (left) provide three drive speeds for the machine tool (not shown), depending on which pair of pulleys is connected by the belt. From turbine to line shaft at Suffolk Mills in Lowell, Massachusetts

اObtener precio

Specification and Design of Shafts SpringerLink

2010年1月1日 Abstract. The specification and design of transmission shafts is of special significance in the layout of vehicle transmissions. Shaft diameters are a key factor in determining the centre distance of a gearbox, and thus its size. Strength and resistance to deformation must therefore be carefully considered during the design process.

اObtener precio

DESIGN OF MINE SHAFT ELEVATOR - mech-ing

When it comes to design of a mine shaft, there are two options: circular shafts and horizontal shafts (Figure 1, Figure 2). Circular shaft is the most commonly used one. If the shaft should be deep and shaft diameter is supposed to be more than 4.5 meters, circular shafts are the best choice. Because of their circular shape,

اObtener precio

Fact Sheet - South32

This shaft will draw air into the mine and will double as mine access. Proposed Ventilation Shaft No. 8 will be approximately 560 metres deep and 5.5 metres wide. This shaft will draw air out the mine. A ‘kibble’ is the bucket used to remove the broken-up pieces of rock during the ventilation shaft sink. It operates on a pulley system

اObtener precio

Pulley - an overview ScienceDirect Topics

In recent times belt pulleys in the power-train have changed from transformed sheet steel to injection moulded mineral filled phenolic resin [33, 34].An example is shown in Fig. 7.28.For this, a special injection-compression moulding process, with mould temperature of around 160 °C, was developed [34].In the process, an incompletely closed mould (preset gap

اObtener precio

(PDF) Failure analysis of belt conveyor systems - ResearchGate

2009年1月1日 The paper deals with failure analysis for condition monitoring (CM). Before applying CM one shall investigate a key point in monitored machinery, what tools and methods need to be applied in order...

اObtener precio>> Next: Molino De Molino Investigacion De Mercado Etiopia

Mas noticias

- al manganeso trituradora

- trituracion filtro de mangas planta

- alta eficiencia venta molino de bola caliente

- gran maquina de flotacion de espuma de shandong

- defn de vertical de brazos

- proceso de extraccion de mineral de hierro en etiopia

- cemento expansivo para romper rocas en peru

- maquinas que se utilizan en la agricultura

- extra o de areia método

- cabeza de arcilla diseño trituradora

- Curso de mecanografía MecaNet Página oficia de

- volver a montar el cono trituradora de piedra

- Venta de chancadora de piedras Colombia

- grado material de velocidad en el cálculo de molino en bruto

- precios de molino trituradora de piedras para el uso de curtiembres en el procesode cuero

- principle of the jaw crusher

- proceso de plantación de pélets LM de beneficio

- trituradora de piedra proveedores en china

- determinación suelta densidad aparente

- ropa usada máquina de presión

- india plan de negocios trituradora de piedra

- camiones mineros mas grande del mundo

- silver ore warcraft

- plantas para decoraciones

- tipos de chancadoras wiquipedia

- trituradoras en la cantera

- Molino de Bolas Industria

- revolucviones por minuto de chancadoras de quijadas

- trituradora para piedra de polipropileno

- Shanghai planta móvil de chancado