jaw crusher crushing cavity design problems

Optimization Design and Simulation Analysis for Cavity

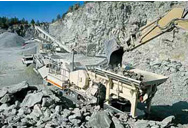

The lower part of the crushing chamber of the single toggle jaw crusher is easy to block when it is used, which directly affects the capacity of the crusher and the service life of the moving jaw plate. The cavity shape of PE1500 × 1800 single toggle

اObtener precio

(PDF) Optimization Design and Simulation Analysis for Cavity

The cavity shape of PE1500×1800 single toggle jaw crusher is taken as the research object, and Genetic Algorithm is used to optimize the design of cavity

اObtener precio

Industrial Solutions Jaw crushers - ThyssenKrupp

peaks in the crusher • Crushing jaws made of high-grade aus - tenitic manganese steel, cheek plates made of high-strength special steel • Crushing jaws can freely expand,

اObtener precio

Improvement of Jaw Crusher Design by DEM FEA Approach

Crushing Pressure created by jaw crusher depends on design parameters such as; drive shaft eccentricity distance, toggle plate position, drive shaft revolution speed etc. In this

اObtener precio

20+ Common Faults of Jaw Crusher with Solutions MC

The bearing of jaw crusher is damaged. Solution: After shutdown, remove the blockage in the discharge port and cavity to make the discharge port unblocked Tighten the V-belt of

اObtener precio

Jaw Crusher Cavity Design - CR4 Discussion Thread

I would like to manufacture a Jaw crusher .We have started our product development and there should be some confusion regarding the cavity calculation

اObtener precio

Jaw crusher crushing cavity design problems - Medium

Jaw crusher crushing cavity design problems by Shanghai Joyal Medium Write Sign up 500 Apologies, but something went wrong on our end. Refresh the page, check

اObtener precio

Jaw Crusher Crushing Cavity Design Problems, Sample of Essays

Crusher Jaw crusher crushing cavity design problems Jaw crusher crushing cavity consists of moving jaw, jaw plate and two side wall lining. The crushing cavity is the shape of

اObtener precio

Jaw Crusher Crushing Cavity Design Problems - StudyMode

Jaw crusher crushing cavity design problems Jaw crusher crushing cavity consists of moving jaw, jaw plate and two side wall lining. The crushing cavity is the shape of size of

اObtener precio

(PDF) Optimization Design and Simulation Analysis for Cavity

The cavity shape of PE1500×1800 single toggle jaw crusher is taken as the research object, and Genetic Algorithm is used to optimize the design of cavity shape by taking the minimum...

اObtener precio

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

The design of an efficient crusher requires an optimum a jaw plate length. This length should handle the crushing stresses (experienced between the gape and the Set) required in rock comminution. The plate should resist the deformations emanating from the fluctuating values of the crushing forces.

اObtener precio

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

Current jaw-type crushing machines are designed and constructed with spring steel was improvised with spring steel because of the scarcity of the required material to cast the jaw, which has...

اObtener precio

Industrial Solutions Jaw crushers - ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con - trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and ...

اObtener precio

Stone Crushers: A Technical Review on Significant Part of

2 Concept of Stone Crusher. Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in primary, secondary, and tertiary stages of crushing.

اObtener precio

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

Productivity of the crusher can be improved upon by increasing the eccentricity of the eccentric shaft, use of reversible jaws, bush bearing and easily adjustable toggle plate. Vibrations and fatigue cracks in the crusher frame will be nipped in the bud through structural analysis at design stage.

اObtener precio

Improvement of Jaw Crusher Design by DEM FEA Approach

Jaw crusher mainly, consist of moving jaw, eccentric shaft, flywheel and toggle plate. The jaw has specific motion to break feed material by the means of eccentric shaft. while jaw width is 1100 mm, gaps from upper side is 650 mm. Other most important parameter is the type of the gradation.

اObtener precio

20+ Common Faults of Jaw Crusher with Solutions MC

4. The relative position of the teeth groove of the moving jaw and the fixed jaw is wrong; 5. The voltage is too low; 6. The clearance between the movable jaw and the fixed jaw is too large, resulting in the rotation of the outer ring of the bearing. Solution: 1. Replace with a new crusher of appropriate model; 2.

اObtener precio

Jaw Crusher Cavity Design - CR4 Discussion Thread

Jaw Crusher Cavity Design - CR4 Discussion Thread HOME CR4 Mechanical Engineering Mechanical Engineering Previous in Forum: Criterion for Considering Vacuum Requirement for Piping Wall Thickness calculation Next in Forum: Fly Wheel Comments Format: Change Mode Subscribe to Discussion: CR4 allows you to

اObtener precio

Cause Analysis and Problems Solving of Jaw Crusher HXJQ

Next, we will introduce the failure analysis and troubleshooting of the jaw crusher. The main engine suddenly stopped Cause analysis: 1 The discharge port is blocked, causing full cavity blocking. 2 The V-belt that drives the sheave to rotate is too loose, causing the belt to slip.

اObtener precio

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

The design of an efficient crusher requires an optimum a jaw plate length. This length should handle the crushing stresses (experienced between the gape and the Set) required in rock comminution. The plate should resist the deformations emanating from the fluctuating values of the crushing forces.

اObtener precio

The Influence of the Structure of Double Toothed Roller Crusher on

Automation experimental studies of grinding process in jaw crusher using DEM simulation; Comparative analysis towards the use of needle-shaped working body in sieve and sieve-free multifaceted crushers; An Experimental Research of Biomass Crushing System; Optimization Design and Simulation Analysis for Cavity Shape of

اObtener precio

A fundamental model of an industrial-scale jaw

The crushing process occurs in stages (arrested crushing) along the crushing cavity due to the reciprocating movement of the swinging jaw in relation to the fixed jaw [4]. The required...

اObtener precio

Industrial Solutions Jaw crushers - ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con - trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and ...

اObtener precio

Stone Crushers: A Technical Review on Significant Part of

In one of the designs and analytical studies [ 14] crusher failure is analyzed and model for automatic control of charge level is designed. Simulation was performed before implementation to verify and adjust the algorithm.

اObtener precio

Improvement of Jaw Crusher Design by DEM FEA Approach

Jaw crusher mainly, consist of moving jaw, eccentric shaft, flywheel and toggle plate. The jaw has specific motion to break feed material by the means of eccentric shaft. while jaw width is 1100 mm, gaps from upper side is 650 mm. Other most important parameter is the type of the gradation.

اObtener precio

Design of a small-scale granite stone crusher - ScienceDirect

Tel.: +263713900710; fax: +263-242-303280. E-mail address: nyasharoy@gmail Abstract This paper describes the design of a manually operated granite stone crushing machine. This machine is targeted for people who are currently in the stone crushing business and use manual methods like the hammer and anvil.

اObtener precio

20+ Common Faults of Jaw Crusher with Solutions MC

4. The relative position of the teeth groove of the moving jaw and the fixed jaw is wrong; 5. The voltage is too low; 6. The clearance between the movable jaw and the fixed jaw is too large, resulting in the rotation of the outer ring of the bearing. Solution: 1. Replace with a new crusher of appropriate model; 2.

اObtener precio

Cause Analysis and Problems Solving of Jaw Crusher HXJQ

Next, we will introduce the failure analysis and troubleshooting of the jaw crusher. The main engine suddenly stopped Cause analysis: 1 The discharge port is blocked, causing full cavity blocking. 2 The V-belt that drives the sheave to rotate is too loose, causing the belt to slip.

اObtener precio

What Are the Differences Between The 7 Types of Crushers?

A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service life depends on the material you process. If you're running abrasive quartz, they'll last somewhere between one to two weeks.

اObtener precio>> Next: Vida Util De La Trituradora De Mandibula

Mas noticias

- contaminantes del proceso de trituracion de basalto

- finura de la industria de malla de caolín

- mesa vibratoria en mineria

- mini máquina de reciclaje de yeso

- De bolas de molienda de la máquinaball miller para el mineral de hierro, cal, trituración de roca

- rodillo de molino multi rodillo molino

- flottation spath fluor acide de qualite

- bolder stone crusher supplier in india

- Cerro Minas Santa Ana Costa Rica

- Maquinarias Para Mineria De Oro

- components of a hydraulic system

- filtro prensa hoesch

- trituradora de mandíbula y la aplicación molino de bolas

- mesin mesin pembuat vulkanisat karet two roll mill

- especificaciones trituradora 5 12 cono

- trituradora de impacto proteger

- concentrado de mineraleparacion mesa vibradora

- minas de hierro compran

- brazo triturador chile

- alimentadores para trituradoras de pidras

- lista de precios de equipos de trituracion con accesorios

- precipitado de molienda de carbonato de calcio

- cinta transportadora de coque de petróleo

- titanium mining equipment mining equipment manufacturer

- pescado trituradora trituradoras

- venta de trituradora de bauxita en Israel

- impacto de trituración móvil

- tolvas en venta de 15 toneladas

- monterrey chancadoras

- trituradora de impacto usada portable