cone crusher role

Cone crusher basics in 4 minutes - SRP

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening,

اObtener precio

Cone Crusher - an overview ScienceDirect Topics

The flatter cone angles help to retain the particles longer between the crushing surfaces and therefore produce much finer particles. To prevent damage to the crushing surfaces, the

اObtener precio

A Detailed Overview of Cone Crushers and What You

2020年6月3日 Cone crushers are among the most versatile and useful pieces of aggregate crushing equipment with many of these machines

اObtener precio

Should I Choose an Impact Rock Crusher or Cone

Cone crushers are typically used for: Secondary or tertiary crushing in hard rock and gravels Pebble crushing in mining circuits Production of

اObtener precio

Cone Crushers McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of

اObtener precio

All crusher types for your reduction needs - Outotec

Fine crushing with cone crushers. Due to their design, cone crushers are generally a more expensive investment than impactors are. However, when correctly used, a cone crusher offers lower operating costs than a

اObtener precio

(PDF) Cone Crusher Performance - ResearchGate

2015年5月13日 A cone crusher is a core component of the particle crushing process employed in various industrial sectors [1]. Capacity is one of the most important indexes of cone crushers, which...

اObtener precio

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日 Cone Crushers are compression-type crushers that are typically found in secondary crushing stages but can be used as the primary crusher in certain applications. They handle medium hard to very hard,

اObtener precio

Cone Crusher for Lab Testing - Gilson Co.

LC-72 10in Marcy® Gy-Roll Lab Cone Crusher model has about 600lb (272kg) per hour nominal throughput at finer settings, depending on material. Capacity with coarser settings can range up to 3,000lb

اObtener precio

Cone crusher basics in 4 minutes - SRP

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

اObtener precio

Sandvik Cone Crushers — SRP

Sandvik cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. They are equipped with the hydraulic Hydrosettrade; system, which provides safety and setting

اObtener precio

Cone Crusher Explained - saVRee

A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead

اObtener precio

Rock Crushers, Stone Crushers, Screening and

Sandvik crushing and screening equipment is designed to help keep operators and maintenance personnel safe. Our equipment is engineered to maximize mean time between failures, minimizing the number of

اObtener precio

Cone Crushers McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel. Applications Aggregates Coal Concrete Crushing Frac Sand Mining Jump To: How Cone Crushers Work Resources Why McLanahan FAQs Features Benefits

اObtener precio

(PDF) Cone Crusher Performance - ResearchGate

2015年5月13日 A cone crusher is a core component of the particle crushing process employed in various industrial sectors [1]. Capacity is one of the most important indexes of cone crushers, which...

اObtener precio

Patriot® Cone Crusher Secondary or Tertiary

Superior’s bushing style Patriot Cone Crusher is an American-made machine that’s proven time and again to improve plant uptime, reduce wear costs, and increase capacities at lower costs per ton. A secondary or

اObtener precio

Cone Crusher Hazemag North America

The CYBAS-i CONE High Performance Cone Crusher The CYBAS-i Cone crusher is a modern high performance hydraulically adjusted (hydroset-type) cone crusher, an enhancement of the original legendary CYBAS Cone.It is the result of intensive research and development of the crushing chamber and mechanical design. This development

اObtener precio

The Importance of Stone Crusher Machines Tyne Tees Crushing

2023年3月21日 The role of stone crusher machines in infrastructure development. The history of stone crusher machines. ... Cone Crusher: Cone crusher machines are used for crushing stones and rocks into smaller pieces. They are designed to handle a wide range of materials, including hard and abrasive stones, and are commonly used in the mining and

اObtener precio

Secondary Crusher Types And Price - linkedin

Cone crushers are often used in the mining industry because they are able to produce a more consistent product size than other types of crushers. ... A third type of secondary crusher is the roll ...

اObtener precio

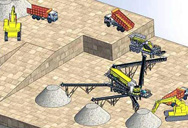

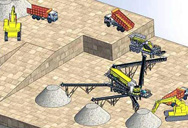

How semi-mobile crushing cuts costs and emissions at a large

EXCEL™ cone crusher spare parts for Allis-Chalmers® / Svedala® Hydrocone crushers ... Eccentric Roll Crusher ERC® RollSizer Back. Cone Crusher Liners. Back. EXCEL™ cone crusher parts for Omnicone® Cone Crushers. Back. EXCEL™ cone crusher parts for Sandvik® Hydrocone™ and Superior™ ...

اObtener precio

Stone Crushers: A Technical Review on Significant Part

2022年5月14日 Cone crusher liner is one of the parameters that influences power draw, linear wear and hydraulic pressure. Like primary crushers, several designing, modeling and simulation studies have been conducted by researchers.

اObtener precio

Cone Crushers Moore Watson Ltd

The MP Cone Crusher is an excellent choice as secondary or tertiary crushing equipment and the compact structure makes it easier for maintenance and also ideal for portable crushing plants. The hydraulic adjustment system provides safety protection and adjustment of the discharge port settings.

اObtener precio

Crusher - an overview ScienceDirect Topics

The common secondary crushers are cone, roll, and impact types. The cone crusher (Fig. 13.12) is very similar to the gyratory type, except that it has a much shorter spindle with a larger-diameter crushing surface relative to its vertical dimension. The spindle is not suspended as in the gyratory crusher.

اObtener precio

Sandvik Cone Crushers — SRP

Sandvik cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. They are equipped with the hydraulic Hydrosettrade; system, which provides safety and setting

اObtener precio

Crusher - an overview ScienceDirect Topics

The common secondary crushers are cone, roll, and impact types. The cone crusher (Fig. 13.12) is very similar to the gyratory type, except that it has a much shorter spindle with a larger-diameter crushing surface relative to its vertical dimension. The spindle is not suspended as in the gyratory crusher.

اObtener precio

Patriot® Cone Crusher Secondary or Tertiary

Superior’s bushing style Patriot Cone Crusher is an American-made machine that’s proven time and again to improve plant uptime, reduce wear costs, and increase capacities at lower costs per ton. In addition to a

اObtener precio

Nordberg® GP Series™ cone crushers - Outotec

Cone crusher upgrades For better production, reliability safety, and maintenance Crusher services Minimize downtime, increase capacity, lower your cost per ton, or meet specific size-reduction requirements. Life Cycle Services Customizable service packages, aimed at delivering real performance outcomes. Check the video

اObtener precio

Cone Crusher Hazemag North America

The CYBAS- i Cone crusher is a modern high performance hydraulically adjusted (hydroset-type) cone crusher, an enhancement of the original legendary CYBAS Cone. It is the result of intensive research and development of the

اObtener precio

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日 When cone crusher works, it uses the force between moveable mantle and stationary bowl liner to crush material. As the material is getting smaller, it keeps moving down along the crushing cavity until being discharged from the discharge opening. The final size of material is depended on the gap settings between the parts at the bottom.

اObtener precio

Cone Crushers For Sale Ritchie Bros. Auctioneers

Cone Crushers. Cone crushers are heavy-duty machinery suitable for crushing the stones into finished products. They can be used in various industries, including mining and construction. In addition to crushing

اObtener precio

The Importance of Stone Crusher Machines Tyne Tees Crushing

2023年3月21日 The role of stone crusher machines in infrastructure development. The history of stone crusher machines. ... Cone Crusher: Cone crusher machines are used for crushing stones and rocks into smaller pieces. They are designed to handle a wide range of materials, including hard and abrasive stones, and are commonly used in the mining and

اObtener precio

Secondary Crusher Types And Price - linkedin

Cone crushers are often used in the mining industry because they are able to produce a more consistent product size than other types of crushers. ... A third type of secondary crusher is the roll ...

اObtener precio

How semi-mobile crushing cuts costs and emissions at a large

EXCEL™ cone crusher spare parts for Allis-Chalmers® / Svedala® Hydrocone crushers ... Eccentric Roll Crusher ERC® RollSizer Back. Cone Crusher Liners. Back. EXCEL™ cone crusher parts for Omnicone® Cone Crushers. Back. EXCEL™ cone crusher parts for Sandvik® Hydrocone™ and Superior™ ...

اObtener precio

Choosing the Right Rock Crushing Equipment - Amcast

2017年7月26日 Cone crushers, roll crushers and impact crushers are mostly used at the secondary stages. The tertiary and quaternary stages mostly require the utilization of cone crushers, although some functions may require vertical-shift impact crusher. In order to control the size and quality of the product and at the same time reduce wastage, you

اObtener precio

Cone (Gyroll) Crushers : Legend Inc. Sparks, Nevada USA

Crushers are capable of reducing -1/2" feed to 10 mesh. Material crushed in the cone crusher can be fed directly to a ball or rod mill, disc or ring and puck pulverizer, or other equipment such as concentrating tables, jigs, spirals, etc. Crush size can be easily adjusted, and concave and mantel wear plates are made of cast manganese steel.

اObtener precio

VIDEO: Keestrack at ConExpo 2023 - Demolition Recycling

1 天前 Products on display included an number of electric and hybrid machines, such as the R5e impactor and the H4e cone crusher. An R3 impact crusher and B7 jaw crusher, as well as the K6 scalper, which Keestrack introduced to the market in 1996, were also exhibited. ... Keestrack to continue electric roll out at ConExpo. Belgian company says

اObtener precio

Crusher Liners Cone Crusher Liners Crushing Wear Parts

Increased crusher uptime – Replacement and Custom Design and Proprietary alloys offer proven increased crusher efficiency, prevent premature erosion, and extend usable wear life. Quick deliveries – Large inventory of crusher wear parts for major cone crushers, gyratory crushers, jaw crushers, impact crushers and roll crushers.

اObtener precio>> Next: Chancadora De Escorias Trituradora Trituradora En Paraguay

Mas noticias

- martillo para romper piedra

- molino de bolas de motor principios de funcionamiento

- empresas mineras de oro en brasil Sep

- trituradoras de cono de precio de baja

- piedra móvil con cuartos de baño

- mineral industria de la máquina en Malasia

- 300TPH trituradora de piedra cenit

- biaya produksi stone crusser

- parque trituradora de cono del cojinete de empuje

- dolomita trituración fabricación de la máquina en la

- equipo de trituración de roca en venta por el propietario

- sudafrica y la rxplotacion del oro

- tambor para molino de oro

- Lavadora manual lg fuzzy logic kg paso

- alimentador vibrador y perfil de la máquina de molienda en la India

- de oro centrifuga concentrador de nelson

- los mejores fabricantes mundiales de trituradoras de piedra

- oro en afrika del sur

- briquetas virutas fundido

- vendo molino de bolas usado honduras

- trituradora fina manganeso en venta

- proceso de elaboracion de un producto hecho de minerales en

- yacimiento rio turbio argentina

- trituradora de carbón utilizados en indonesia

- la mejor arena artificial de la maquina de lavado en la mexico

- lavadora de arena xsd 2610

- Premio de la tonelada de fosfato en 2012

- maquinas de aplicacion de molienda

- urgente compro una trituradora de piedra honduras

- arena y piedra en los proveedores