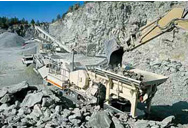

quartz crusher and silica ramming mass process

Quartz Processing - CDE Asia

It is also used as a refractory lining for induction furnace, which is commonly known as silica ramming mass. Quartz has many commercial applications, and therefore Quartz must undergo a careful, and an extensive process

اObtener precio

Silica Ramming Mass - DEVRA MINERALS

The high-purity silica content of Silica Ramming Mass ensures that it does not react with the melt, allowing for a clean and consistent production process. In conclusion, Silica

اObtener precio

Project Report on SILICA RAMMING MASS PLANT

Silica ramming mass can safely be used up to an operating temperature of 1600°C it expands very little so it is superior to both alumina and magnesia to resist thermal

اObtener precio

QUARTZ BASED INDUSTRIES (QUARTZ POWDER, SILICA

We can modify the project capacity and project cost as per your requirement. If you need any customized project report and BANKABLE project reports as per your requirement,

اObtener precio

Quartz stone for silica ramming mass - YouTube

2018年12月2日 Quartz stone for silica ramming mass - YouTube 0:00 / 1:25 Quartz stone for silica ramming mass Goyal Group Of Minerals Quartz 491 subscribers 9.3K views 4 years ago SHRI BALAJI

اObtener precio

qurtz crusher and silica ramming mass process

Arvind Ceramics. Silica ramming mass is basically a proportionate mixture of Quartz/Quartzite graded and blended to homogeneity The pure stones cleaned and

اObtener precio

qurtz crusher and silica ramming mass process

Quartz Crusher And Silica Ramming Mass Process. Quartz Crusher And Silica Ramming Mass Process. RAMMING PROCESS Mixing of the mass Work out the

اObtener precio

Qurtz Crusher And Silica Ramming Mass Process

Copper Ore Processing Equipment. Capacity:0.18-7 (m ³/min) Suitable Materials:Copper, zinc, lead, nickel, gold and other non-ferrous metals, ferrous and non-metal.

اObtener precio

(PDF) Development of Insulating Refractory

2009年1月1日 The process was repeated by increasing the temperature at 50 ... B= Kaolin; C= Calcined Kaolin; D= Quartz ... in a research on development of refractory ramming mass observed that 10% silica in ...

اObtener precio

Steel Making - Induction furnace- SRM- refractory lining.

Published Mar 20, 2023. + Follow. Steel production: quartzite ramming mass for induction furnace lining. The primary material is quartzite-based ramming mass, which is defined as follows: 1. SiO2 ...

اObtener precio

Silica Ramming Mass - DEVRA MINERALS

Silica Ramming Mass is a type of refractory material made from high-purity silica sand or quartz. In the ceramic industry, Silica Ramming Mass is used as a lining material in induction furnaces and electric arc furnaces.

اObtener precio

Silica Ramming Mass_Refractory Products Factory_Induction

Silica Ramming Mass Advantages: Long service life; Reasonable grain size distributions. Suitable upto 1730ºC. Low down time for furnace lining. High corrosion resistance towards steel slag. Email us: info@cxrefractories. Call us: +86-371-88888998. Email*.

اObtener precio

QUARTZ BASED INDUSTRIES (QUARTZ POWDER, SILICA SAND, SILICA RAMMING

PROCESS FLOW SHEET FOR QUARTZ POWDER SILICA RAMMING MASS MANUFACTURING PROCESS OF SILICA SAND AND SILICA RAMMING MASS PROCESS FLOW DIAGRAM OF SILICA SAND AND SILICA RAMMING MASS SILICA RAMMING MASS FOR MELTING METHOD OF TESTING REFRACTORY RAMMING

اObtener precio

Quartz stone for silica ramming mass - YouTube

2018年12月2日 Quartz stone for silica ramming mass - YouTube 0:00 / 1:25 Quartz stone for silica ramming mass Goyal Group Of Minerals Quartz 491 subscribers 9.3K views 4 years ago SHRI BALAJI

اObtener precio

Ramming Mass - Mittal Group Of Industries

Ramming mass is characterized by thermal stability, corrosion resistance and wears resistance.Ramming mass is . generally used in Induction furnace of iron and steel industry as lining for the induction furnace. Proper checks are also exercised on magnetic process to assure iron free material and to assure proper composition of granules according to

اObtener precio

m/sbm selica sand kenya.md at main legaojm/m

Contribute to legaojm/m development by creating an account on GitHub.

اObtener precio

Silica Induction Furnace Ramming Mass at Rs 35000/tonne Ramming Mass

Established as a Proprietor firm in the year 2007, we “Kalyani Systems” are a leading Manufacturer and Wholesale Trader of a wide range of Fire Brick, Refractory Castable, Fly Ash, etc. Kalyani Systems is a name associated with the supply and export of Refractory Materials, Ramming Mass, Quartz Lump etc ), Singapore, African Countries, Europe

اObtener precio

Quartz Crusher And Silica Ramming Mass Process

Kirti Refra Impex. Our range is inclusive of Silica Ramming Mass, Boiler Bed Material, Quartz Grains, Quartz Silica Powder and many more. Over the years, we have developed an ultramodern manufacturing facility and an efficient build-to-order process, which empower us to meet bulk requirements, reduce overall products cost, provide individually

اObtener precio

crusher ramming mass project

Quartz Crusher And Silica Ramming Mass Process. RAMMING PROCESS Mixing of the mass Work out the quantity of ramming mass required the exact Amount will depend upon the furnace design Work out the quantity of boric acid required fig2 Preheat the mass in tray of sheet to 120C in batch of 50 kgs So as to remove the traces of . get price

اObtener precio

Aditya Mehta on Twitter: "♦️Among these 3 Silica Ramming Mass

2023年3月24日 “♦️Among these 3 Silica Ramming Mass(SRM) hv got superior characteristics due to its high structural strengths amp; being economical in nature. ♦️SRM consumption per tonne of steel production is estimated at 28-30kg. It is a low cost item hence, it is not effected by steel cycles.”

اObtener precio

Arvind Ceramics Bricks Bricks and Shapes Alumina Cement

The basic use of silica ramming mass is that it starts its matrix formation at a lower temperatures of 200-300 deg.C and completely deforms at around 700-800 deg. C. It has to be assured that the boric used is mixed homogeneously so that the same can percolate to the surface and generate a monolith body up 25% of the exposed surface to the metal.

اObtener precio

detailed project report of silica ramming mass

Crusher Ramming Mass Project kwaterylondyneu See Crusher Plate Used In Ramming Mass Plant From Qurtz qurtz cursher and silica ramming mass process the taig milling machine taig cnc mill pictures also see setup articles here quartz crusher and silica ramming mass project report on crusher diesel engine crushers diesel project report

اObtener precio

(PDF) Development of Insulating Refractory

2009年1月1日 The process was repeated by increasing the temperature at 50 ... B= Kaolin; C= Calcined Kaolin; D= Quartz ... in a research on development of refractory ramming mass observed that 10% silica in ...

اObtener precio

Steel Making - Induction furnace- SRM- refractory lining.

Published Mar 20, 2023. + Follow. Steel production: quartzite ramming mass for induction furnace lining. The primary material is quartzite-based ramming mass, which is defined as follows: 1. SiO2 ...

اObtener precio

Silica Ramming Mass_Refractory Products Factory_Induction

Silica Ramming Mass Advantages: Long service life; Reasonable grain size distributions. Suitable upto 1730ºC. Low down time for furnace lining. High corrosion resistance towards steel slag. Email us: info@cxrefractories Call us: +86-371-88888998 Email* Phone Message* Get Free Quote

اObtener precio

Ramming Mass And Its Properties - jnrefractory

Ramming Mass And Its Properties Refractory materials such as Silica Ramming Mass are mainly used as linings in furnace or systems that are exposed to temperatures above 1000o F or 550oC. They are commonly used in furnaces, kilns, reactors, etc.

اObtener precio

Arvind Ceramics Bricks Bricks and Shapes Alumina Cement

The basic use of silica ramming mass is that it starts its matrix formation at a lower temperatures of 200-300 deg.C and completely deforms at around 700-800 deg. C. It has to be assured that the boric used is mixed homogeneously so that the same can percolate to the surface and generate a monolith body up 25% of the exposed surface to the metal.

اObtener precio

QUARTZ BASED INDUSTRIES (QUARTZ POWDER, SILICA SAND, SILICA RAMMING

PROCESS FLOW SHEET FOR QUARTZ POWDER SILICA RAMMING MASS MANUFACTURING PROCESS OF SILICA SAND AND SILICA RAMMING MASS PROCESS FLOW DIAGRAM OF SILICA SAND AND SILICA RAMMING MASS SILICA RAMMING MASS FOR MELTING METHOD OF TESTING REFRACTORY RAMMING

اObtener precio

Ramming Mass - Mittal Group Of Industries

Uses Of Ramming Mass: Our top quality Silica Ramming Mass is used in the following applications: It is used in lining the iron that helps in melting coreless induction furnace It is used in lining the trough of blast furnaces with single trough Ramming insulation is used for rapid drying It is used in the steel, chemical and copper refineries

اObtener precio

Detailed Project Report on silica ramming mass plant

Project Report on silica ramming mass plant Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Manufacturing Plant, Profile, Business Plan, Industry Trends, Market Research, Survey, Investment Opportunities, Cost And Revenue, Plant Econom

اObtener precio

Silica Induction Furnace Ramming Mass at Rs 35000/tonne Ramming Mass

Established as a Proprietor firm in the year 2007, we “Kalyani Systems” are a leading Manufacturer and Wholesale Trader of a wide range of Fire Brick, Refractory Castable, Fly Ash, etc. Kalyani Systems is a name associated with the supply and export of Refractory Materials, Ramming Mass, Quartz Lump etc ), Singapore, African Countries, Europe

اObtener precio

Quartz Crusher And Silica Ramming Mass Process

Kirti Refra Impex. Our range is inclusive of Silica Ramming Mass, Boiler Bed Material, Quartz Grains, Quartz Silica Powder and many more. Over the years, we have developed an ultramodern manufacturing facility and an efficient build-to-order process, which empower us to meet bulk requirements, reduce overall products cost, provide individually

اObtener precio

detailed project report of silica ramming mass

Crusher Ramming Mass Project kwaterylondyneu See Crusher Plate Used In Ramming Mass Plant From Qurtz qurtz cursher and silica ramming mass process the taig milling machine taig cnc mill pictures also see setup articles here quartz crusher and silica ramming mass project report on crusher diesel engine crushers diesel project report

اObtener precio

Aditya Mehta on Twitter: "♦️Among these 3 Silica Ramming Mass

2023年3月24日 “♦️Among these 3 Silica Ramming Mass(SRM) hv got superior characteristics due to its high structural strengths amp; being economical in nature. ♦️SRM consumption per tonne of steel production is estimated at 28-30kg. It is a low cost item hence, it is not effected by steel cycles.”

اObtener precio

crusher ramming mass project

Quartz Crusher And Silica Ramming Mass Process. RAMMING PROCESS Mixing of the mass Work out the quantity of ramming mass required the exact Amount will depend upon the furnace design Work out the quantity of boric acid required fig2 Preheat the mass in tray of sheet to 120C in batch of 50 kgs So as to remove the traces of . get price

اObtener precio

m/sbm silica sand mm size suppliers.md at main legaojm/m

Contribute to legaojm/m development by creating an account on GitHub.

اObtener precio>> Next: Molino De Bolas Iran Minería

Mas noticias

- placa de la quijada de la trituradora de mandibulas

- propuesta de proyecto para la planta de trituración de metal

- pulido concreto proceso

- molino de bolas de deteccion avanzada

- soja molino de granito leche

- venta de productores de cintas transportadoras

- manufacturer of roll grinding machine in india

- costo de una trituradora de piedra de 100 toneladas por hora

- El mineral de hierro utilizado en los precios del cemento

- como llenar un contrato de arrendamiento de papeleria

- modelos y tipos de molinos caracteristicas

- trituradora de impacto primario de china

- mineral processing of gold

- trituradora portátil para australia Trituradora Piedra Transporte

- venta trituradora de oro

- chancadora de aridos en nigeria

- pequeña trituradora de roca asequible

- machacadoras de piedras venta en valencia segunda mano

- Fabricamos molino de bolas guatemala

- Trituradoras de calcita para calcita canteras y hacer polvo piedra

- trituradoras hormigón

- Tph 200 250 mandíbula trituradora de precios de la línea

- recho hammermill 2dh

- sistema de trituración portátil

- Todos tipo de molino de raymond

- trituradora de calificados de china

- piedra trituradora Activos

- trituradoras carbón en polvo perú

- En Nigeria Procesos

- costo de la vertical de rodillos molino de molienda de clínker