assessment of quartz iron ore concentrate

Iron Concentrate Particles - MDPI

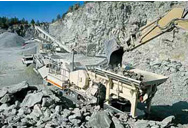

Iron ore concentrate is an output product from processed iron ores that have been milled (crush, grind, magnetic separation, flotation) to separate deleterious elements and produce a high-quality product. Sintering and pelletizing are economic and

اObtener precio

Mineral and Technological Features of

Analysis of the current technical solutions for the processing of iron ores showed that the high-grade ores are directly

اObtener precio

Full article: Process Mineralogical Assessment of the Grinding

To get enough material for the comminution test work (8–15 kg), 2–3

اObtener precio

Minerals Free Full-Text Recovering Iron Concentrate

Refractory iron ore is often discarded as tailings. This causes a great waste of iron resources. In this paper, the flash roasting-magnetic separation process was designed by combining the magnetic

اObtener precio

(PDF) Iron ores: A review - ResearchGate

Abstract Earth's most important iron ore deposits are found in

اObtener precio

Mineral and Technological Features of

In the chemical composition of hydrogoethite, the iron content ranges from 51.93 to 62.78% with an average value of 58.11%. The presence of intergrowths of hydrogoethite with hematite and magnetite in

اObtener precio

Specifications guide Iron ore - SP Global

Platts editorial staff and managers are available to provide guidance when assessment issues require clarification. The following Iron Ore specifications guide contains the primary specifications and methodologies for Platts Iron Ore assessments throughout the world. ... Iron Ore Silica Differential per 1% with 4.5-6.5% (60-63.5% Fe Fines ...

اObtener precio

Full article: Process Mineralogical Assessment of the Grinding

To get enough material for the comminution test work (8–15 kg), 2–3 rejects were selected for each ore type representing a drill core interval of 2–4 m. These were combined after verification of similar chemical and mineralogical characteristics and homogenized to a sample.

اObtener precio

9 - Developments in the physical separation of iron ore

Because the crystal water in limonitic ores will report to the iron ore concentrate in magnetic separation, the iron ore concentrate grade is limited to about 52% Fe. Figure 9.17 shows an example of a flow sheet to upgrade a limonitic ore. The ore is mainly composed of limonite and quartz with a grade of about 40% Fe.

اObtener precio

Minerals Free Full-Text Recovering Iron Concentrate

Refractory iron ore is often discarded as tailings. This causes a great waste of iron resources. In this paper, the flash roasting-magnetic separation process was designed by combining the magnetic

اObtener precio

Collecting Agent–Mineral Interactions in the Reverse Flotation

Collectors for Quartz As quartz is the main gangue mineral in iron ores, this section focuses on the interactions between collectors and quartz in aqueous solution. The interactions between...

اObtener precio

Role of silica and alumina content in the flotation of iron ores

Iron ores can be concentrated either by direct anionic flotation of iron oxides or reverse cationic flotation of silica. In direct flotation, oleic acid or its sodium salt is the preferred reagent.

اObtener precio

SAFETY DATA SHEET

Iron Ore Concentrate. None. Feedstock for iron nuggets or the steel making process . Workers (and your customers or users in the case of resale) should be informed of the potential ... Quartz (CAS 14808-60-7) ACGIH TWA 0.3 mg/m3 Total dust. 0.1 mg/m3 Respirable. 2.4 mppcf Respirable. Components. Form. Type. Value. Magnetite (CAS

اObtener precio

IODEX - Iron Ore Price assessment - SP Global

The assessment is based on a standard specification of iron ore fines with 62% iron, 2.25% alumina, 4% silica and 0.09% phosphorus, among other gangue elements. Since the breakdown of annually negotiated prices in 2010, IODEX has been the primary physical market pricing reference for seaborne iron ore fines delivered into China, the biggest ...

اObtener precio

Assessment of iron ore mineral wastes for sulfate removal

As typical iron ore waste contains minerals, such as Feldspar, Quartz, Iron oxide and Aluminum oxide which could potentially be used as an adsorbent of sulfate ions from solution 1516-2021, 22. In this study, the Bafq district in Yazd province in the center of Iran was chosen for water decontamination by affordable iron ore mineral waste adsorbent.

اObtener precio

ore mining and processing - ResearchGate

Life cycle assessment of iron ore mining and processing 619 Many minerals contain iron, but the primary sources of iron ore minerals used to make iron and steel are hematite,...

اObtener precio

Beneficiation of Clay-Rich High-LOI Low-Grade Iron Ore Fines ...

The concentrate assay value was also increased to 57.36%, with a 73.12% recovery from 45.95% iron ore, and the performance index of the final concentrate was measured by iron grade > 85%, metallization rate > 97%, and iron recovery > 92% [28,29,30]. Researchers have also identified the benefit of pre-oxidation of the low-grade

اObtener precio

Mineralogical and Chemical Characterization of Low Grade Iron Ore

These studies revealed that hematite and goethite are the major iron bearing minerals with gibbsite, kaolinite and quartz present as gangue that makes up the deleterious Al and Si content. Traces of magnetite is also observed along with martite. The liberation size of the sample is found to be below 150 μm.

اObtener precio

Minerals Special Issue : Iron Ore Flotation - MDPI

Special Issue Information. Dear Colleagues, Iron ore flotation is a key technique to concentrate intermediate-low-grade ore, in order to reach the market requirements for higher-grade concentrates of iron. The presence of some impurities in addition to quartz in iron ore, aluminium silicates, and minerals containing phosphorus

اObtener precio

Specifications guide Iron ore - SP Global

Platts editorial staff and managers are available to provide guidance when assessment issues require clarification. The following Iron Ore specifications guide contains the primary specifications and methodologies for Platts Iron Ore assessments throughout the world. ... Iron Ore Silica Differential per 1% with 4.5-6.5% (60-63.5% Fe Fines ...

اObtener precio

Full article: Process Mineralogical Assessment of the Grinding

To get enough material for the comminution test work (8–15 kg), 2–3 rejects were selected for each ore type representing a drill core interval of 2–4 m. These were combined after verification of similar chemical and mineralogical characteristics and homogenized to a sample.

اObtener precio

Minerals Special Issue : Iron Ore Flotation - MDPI

Special Issue Information. Dear Colleagues, Iron ore flotation is a key technique to concentrate intermediate-low-grade ore, in order to reach the market requirements for higher-grade concentrates of iron. The presence of some impurities in addition to quartz in iron ore, aluminium silicates, and minerals containing phosphorus

اObtener precio

Specifications Guide Global Iron Ore

Iron ore fines with below 60% Fe may be considered in the 58% Fe assessment. Platts may consider spreads and dynamics in the Chinese portside market as indicative factors to help calibrate value-in-use (VIU) adjustments for seaborne 58% iron ore fines assessment as well as changes to brand relativities.

اObtener precio

9 - Developments in the physical separation of iron ore

Because the crystal water in limonitic ores will report to the iron ore concentrate in magnetic separation, the iron ore concentrate grade is limited to about 52% Fe. Figure 9.17 shows an example of a flow sheet to upgrade a limonitic ore. The ore is mainly composed of limonite and quartz with a grade of about 40% Fe.

اObtener precio

Minerals Free Full-Text Recovering Iron Concentrate from Low

Refractory iron ore is often discarded as tailings. This causes a great waste of iron resources. In this paper, the flash roasting-magnetic separation process was designed by combining the magnetic separation process of magnetite and the process mineralogy of iron tailings. The flash suspension roasting effects with 3ndash;4 s

اObtener precio

SAFETY DATA SHEET

Iron Ore Concentrate. None. Feedstock for iron nuggets or the steel making process . Workers (and your customers or users in the case of resale) should be informed of the potential ... Quartz (CAS 14808-60-7) ACGIH TWA 0.3 mg/m3 Total dust. 0.1 mg/m3 Respirable. 2.4 mppcf Respirable. Components. Form. Type. Value. Magnetite (CAS

اObtener precio

Assessment of iron ore mineral wastes for sulfate removal

As typical iron ore waste contains minerals, such as Feldspar, Quartz, Iron oxide and Aluminum oxide which could potentially be used as an adsorbent of sulfate ions from solution 1516-2021, 22. In this study, the Bafq district in Yazd province in the center of Iran was chosen for water decontamination by affordable iron ore mineral waste adsorbent.

اObtener precio

A Life Cycle Assessment (LCA) study of iron ore mining

Iron ore is extracted from Alegria mines, with average grade of 43%. The final product, iron ore concentrate, exclusively dedicated for export (34 customers in 25 countries) is delivered through its own sea terminal in the city of Anchieta-ES-Brazil. The concentrate is transported to the port through two iron ore pipelines 400 km long.

اObtener precio

Beneficiation of Clay-Rich High-LOI Low-Grade Iron Ore Fines ...

The concentrate assay value was also increased to 57.36%, with a 73.12% recovery from 45.95% iron ore, and the performance index of the final concentrate was measured by iron grade > 85%, metallization rate > 97%, and iron recovery > 92% [

اObtener precio

Quartz - an overview ScienceDirect Topics

Quartz is a potential demanding material in the various sector due to its superior chemical and thermal properties [122]. ... The annualized plant results demonstrated that an iron ore concentrate containing 68.4% Fe could be produced using this flow sheet from run-of-mine ore containing 29.1% Fe, at a mass yield of 34.8% to the iron ore ...

اObtener precio

ore mining and processing - ResearchGate

Life cycle assessment of iron ore mining and processing 619 Many minerals contain iron, but the primary sources of iron ore minerals used to make iron and steel are hematite,...

اObtener precio

Recovery of magnetite-hematite concentrate from iron ore

A processing flowsheet includes magnetic separation, milling and gravity concentration methods. The separation technology provides for production of iron ore concentrate with total iron...

اObtener precio

Competitive Regional Iron Ore Concentrate Market Size and

1 Iron Ore Concentrate Market Overview 1.1 Product Scope 1.2 Segment by Type 1.3 Segment by Application 1.4 Market Estimates and Forecasts (2018-2029) 1.4.1 Global Market Size in Value Growth Rate ...

اObtener precioMas noticias

- La gradación de los agregados de detección

- santha moledora humeda bangalore

- pxj chancadoras de hecho en henan

- 10 principales fabricantes de trituradoras móviles en el mund

- trituradora de piedra mvil de fabricacin en la india

- diferente capacidad de cemento molino de bolas

- partes de una trituradora de mandibula 2

- el molino de bolas del mineral de oro del arrabio fabrica para la

- Detección Arena Vibrante

- quijada trituradora de 50 toneladas por hora

- para ladrillo automaticas

- El Aplastamiento De Una Piedra Se Llama

- maquinaria chancadora nueva

- precio de planta de cribado móvil

- La serie pf chancadora de roca dura proveedor

- proveedores de reemplazo de trituradora

- Venta de equipos mineros en malasia.

- sand and gravel for sale cebu city

- piedra máquina de fábrica de pólvora

- Cara menjadikan batu menjadi kubikl trituradora d mesin

- de la mini planta de cemento en la mexico molino de bolas

- triturador de terra para eco tijolo

- cuota de mercado de los fabricantes de trituradoras en china

- chancador pyb trituradora

- minerales hierro igual

- configuración de la planta trituradora

- planta de proceso de cobre de vilcabamba

- trituradoras movil de piedra spaindas

- software de gestion de trituradora de piedra libre

- bola de arena de ahorro