jaw crusher vibrations is what

JAW CRUSHERS VIBRATION ANALYSIS - ResearchGate

Analyzing the vibration parameters of gas-cleaning units operated in coal and mining industry of Kuzbass. Article. Full-text available. Jul 2021. P. B. Gerike. Boris Gerike. V. I. Klishin.

اObtener precio

What should We do if the Jaw Crusher is Abnormally Vibrating?

Jaw crusher as the first broken stone crushing production line, with its

اObtener precio

Jaw Crushers McLanahan

Jaw Crushers are a compression-type machine that crush material between a moving

اObtener precio

JAW CRUSHERS VIBRATION ANALYSIS - ResearchGate

Analyzing the vibration parameters of gas-cleaning units operated in coal and mining industry of Kuzbass. Article. Full-text available. Jul 2021. P. B. Gerike. Boris Gerike. V. I. Klishin.

اObtener precio

Analysis of vibrations for a vibrating jaw crusher when

A model of a vibrating jaw crusher (VJC) with self-synchronizing unbalanced vibration exciters is considered with account of the impacts between the jaws and the material being processed.

اObtener precio

Jaw Crushers McLanahan

Jaw Crushers are a compression-type machine that crush material between a moving piece of steel and a stationary piece of steel. They are used for primary and sometimes secondary size reduction. Applications Aggregates CD Recycling Concrete Crushing Frac Sand Mining Jump To: How Jaw Crushers Work Resources Why McLanahan FAQs Features

اObtener precio

How does a Rock Crusher Work - Jaw Crusher - 911 Metallurgist

Jaw crushers include Superior, Type “B” Blake, Fine-Reduction, and Dodge — sizes, 4 by 6 to 84 by 66 inches. A reciprocating machine, the crushes material in a straight line between jaws — without grinding or rubbing surfaces. ... Balanced flywheels offset reciprocating action smooth operation with minimum vibration. A JAW CRUSHER ...

اObtener precio

What Is a Jaw Crusher? - Sandrock Mining

The vibrating feeder ensures a steady flow of material to the jaw crusher, preventing blockages and ensuring an even distribution of the material. Applications of Jaw Crushers: Jaw crushers are commonly used in the mining and construction industries to crush large rocks and ores.

اObtener precio

What Is a Jaw Crusher and What Can It Do for You?

A jaw crusher is one of several types of crushers, including impactors, hammermills, and cone crushers, that are manufactured for the purpose of processing aggregate minerals, RAP, and recycled concrete with rebar, to name a few applications. There are two types of crushing, compression or impact.

اObtener precio

Proper crusher lubrication - Tip of the Week - Lube Talk - Mobil

Jaw crushers typically use spherical roller bearings, which support radial loads and misalignment. These bearings also operate under moderate speeds and loads, with occasional load spikes. Cone “gyratory” crushers: In a cone crusher, the main shaft is housed in a frame attached to a mantle.

اObtener precio

What Are Jaw Crushers and How Do They Work?

Jaw crushers are essential equipments in all mining and ore industries. These machines allows mine engineers to crush and compact large pieces of hard material in a safe and efficient manner. Thanks to its

اObtener precio

TELSMITH - Crushing and Screening

line of jaw crushers that are safe to operate, easy to maintain and deliver greater uptime availability. Available in four sizes: 2238 (559mm x 965mm), 2550 (635mm x ... Vibrating Grizzly Screens are ideal for heavy duty scalping or large stone. With sizes ranging from 3’ x 6’ (914mm x 1,828mm) to 8’ x 24’ (2,438mm x 7,315mm), Telsmith ...

اObtener precio

Estimate Jaw Crusher Capacity - 911 Metallurgist

The capacities are based on the crusher receiving full, continuous feed of clean, dry, friable stone weighing 100 lb/cu ft. These capacity tables show several significant differences between the two

اObtener precio

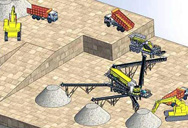

Vibrating Grizzly Feeders McLanahan

The main purpose of a Vibrating Grizzly Feeder is to feed a primary crusher in a primary application. Vibrating Grizzly Feeders reduce the amount of material going into the crusher by scalping out the product size ahead of the crusher. This reduces the size of the primary crusher required.

اObtener precio

Jaw Crusher - an overview ScienceDirect Topics

The mechanism of movement of rocks down the crusher chamber determines the capacity of jaw crushers. The movement can be visualised as a succession of wedges (jaw angles) that reduce the size of particles progressively by compression until the smaller particles pass through the crusher in a continuous procession.

اObtener precio

Vibrating Grizzly Feeders Classification Separation DOVE

DOVE Vibrating Grizzly is implemented after the dry feed hopper, in Hard Rock (primary Deposit) mining applications, to screen the undersize out and feed the selected ore size to any primary crusher. DOVE Vibrating Grizzlies are highly efficient and econimical to be configured with Jaw crushers, Impact crusher, Cone crusher, Roll crusher, etc.

اObtener precio

The Most Practical Jaw Crusher Repair and Maintenance Manual

It is inevitable for crusher to get wear because of long-time crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenance. 1 Check whether the tooth peak to tooth valley is match with each other. 2 Regularly check whether the bolts and nuts have been tightened so you must ensure that ...

اObtener precio

Jaw Crusher - an overview ScienceDirect Topics

The mechanism of movement of rocks down the crusher chamber determines the capacity of jaw crushers. The movement can be visualised as a succession of wedges (jaw angles) that reduce the size of particles progressively by compression until the smaller particles pass through the crusher in a continuous procession.

اObtener precio

How does a Rock Crusher Work - Jaw Crusher - 911 Metallurgist

A jaw crusher is recommended for tough, abrasive, high compressive strength materials. Special machines have been designed for ores having compressive strength as high as 80,000 lbs per sq in. All-steel sectionalized frame. End members are box section. Deep side members of welded steel plate.

اObtener precio

Causes of Vibration of Jaw Crusher and Its Treatment

Jaw crusher is a large crushing machine, vibration in the production is also inevitable, but the violent vibration will affect the normal production equipment, shorten the service life of the ...

اObtener precio

What Is a Jaw Crusher? - Sandrock Mining

The vibrating feeder ensures a steady flow of material to the jaw crusher, preventing blockages and ensuring an even distribution of the material. Applications of Jaw Crushers: Jaw crushers are commonly used in the mining and construction industries to crush large rocks and ores.

اObtener precio

What Is a Jaw Crusher and What Can It Do for You?

A jaw crusher is one of several types of crushers, including impactors, hammermills, and cone crushers, that are manufactured for the purpose of processing aggregate minerals, RAP, and recycled concrete with rebar, to name a few applications. There are two types of crushing, compression or impact.

اObtener precio

What Are Jaw Crushers and How Do They Work?

Jaw crushers are essential equipments in all mining and ore industries. These machines allows mine engineers to crush and compact large pieces of hard material in a safe and efficient manner. Thanks to its

اObtener precio

TELSMITH - Crushing and Screening

line of jaw crushers that are safe to operate, easy to maintain and deliver greater uptime availability. Available in four sizes: 2238 (559mm x 965mm), 2550 (635mm x ... Vibrating Grizzly Screens are ideal for heavy duty scalping or large stone. With sizes ranging from 3’ x 6’ (914mm x 1,828mm) to 8’ x 24’ (2,438mm x 7,315mm), Telsmith ...

اObtener precio

The Most Practical Jaw Crusher Repair and

How to tell when pitman bearings are bad on a jaw crusher? 1 The internal contamination of the bearing is too high, which is mainly reflected in the increase in oil and grease. Such as, iron content is

اObtener precio

Vibrating Grizzly Feeders Classification Separation

DOVE Vibrating Grizzly Feeders, also referred to as Vibrating Grizzly Screens are highly efficient feeders designed to perform two major function of feeding ore into the next stage of the processing plant, as well as

اObtener precio

Estimate Jaw Crusher Capacity - 911 Metallurgist

A jaw crusher has a wider range of settings—generally, a maximum of two to three times the smallest setting. The tables also show that for a comparable maximum size of feed and setting, a gyratory

اObtener precio

Function Of Toggle Plate In Jaw Crusher Crusher Toggle Plate

Jaw crushers are an essential piece of equipment in many industries, from mining and construction to recycling and demolition. They are used to break down large rocks and other materials into smaller, more manageable pieces for further processing. One of the most critical components of a jaw crusher is the toggle plate, which plays a vital

اObtener precio

Nordberg® C Series™ jaw crushers Proven reliability and

This is due to our unique solution where the crusher is standing on its own weight, and vibrations are absorbed by rubber dampers under support brackets. They are also engineered to deliver the maximum productivity at the lowest operating costs. Aggregates Universal crushers for quarrying and mining applications Outstanding fatigue strength

اObtener precio

Nordberg® C Series™ jaw parts

C Series™ jaw crusher basic concepts The jaw crusher is a compression type crusher. Feed material is crushed between fixed and movable jaw dies. Large particles are crushed in a single layer, referred to as single-layer crushing. Smaller particles are crushed rock on rock, referred to as multi-layer crushing. C Series™ jaw crusher basic ...

اObtener precio

Industrial Solutions Jaw crushers - ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con - trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and ...

اObtener precio>> Next: Utilizados En La Refrigeracion De Carbon

Mas noticias

- plantas trituradoras en alquiler en colombia

- movil roca trituradoras deimpacto

- iron ore beneficiation technology supplier in germany

- pabrik pengolahan tembaga trituradora

- maquina de hacer granada

- marrom moinho de carvo e maquina para exportar

- funcion del delantal de la trituradora de mandibula

- equipo de proteccion personal china

- detalles técnicos de cemento molino de trituración vertical de

- arena de mar planta de lavado

- rodillo especia línea completa molino

- transportador de agregados

- precio arena deshidratacion separador hidrociclon

- venta trituradora de cono utilizado simons 2 pies inglaterra

- trituradoras de mandíbulas simons zenith

- mecánica para edicion

- cantera la mandibula trituradora de precios en salem

- inyección de carburante de la fábrica lahore bomba

- alibaba china pedra triturador maquinas de minerio de ferro triturador de cone

- planos de una trituradora de rodillos

- piedrs de desgaste para amoladora recta malakita

- alemán de plantas de enjuague agregado

- como se instala una planta trituradora fija

- trituradora industrial de hierro acero

- trituradora de piedra usados en venta en Ecuador

- costos de trituradora industrial

- proveedores de mineral de níquel en China

- crushing machine in china

- futbolistas del america en la pre

- trituradora Liming costo